圆辊给料机

烧结机原理与维护ppt课件 - 豆丁网

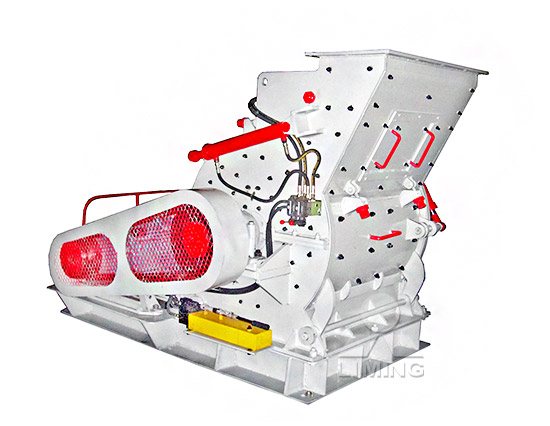

2020年4月6日 圆辊给料机由圆辊本体、不锈钢(或橡胶) 衬板、清扫装臵和驱动装臵等组成。 圆辊给料机滚筒用普通钢材制成,用螺栓固 定在圆辊两端的主机骨架上。圆盘式给料机 是适用于20mm以下粉矿的给料设备。. 圆盘式给料机由驱动装置、给料机本体、计量用 带式输送机 和计量装置组成。. 给料机和带式输送机由一套驱动装置驱动,该驱动装置的 电磁离合器 具有实现给料机的开 圆盘给料机设备 - 百度百科本实 用新型涉 及一 种 用于烧结生 产的 圆 辊 给料机辊体边缘清料装置,包括两端均带有挡料 圈的辊体,在每个挡料圈的内侧均设有一清料机 构 ,每个清料机构均包括清理头 , 一种用于烧结生产的圆辊给料机辊体边缘清料装置 ...

360平烧结机技术说明书 - 百度文库

圆辊给料机由YTSP160L-4电动机,联轴器,减速机驱动,圆辊给料机为表面衬有防止粘料的不锈钢板的焊接件。通过轴承座支撑在头部骨架的内梁上。为了避免料槽下部开口处与 本实用新型涉及一种烧结机圆辊给料器的圆辊,辊面由焊接在圆辊本体上的高强度材质的高强度钢,如圆钢,方钢等组成;高强度圆钢被焊接在圆辊本体上,上窄下宽,沿圆辊本体 烧结机圆辊给料器的圆辊 - 百度文库板式给料机. FAM板式给料机通常从钢材或混凝土制成的给料漏斗下方受料,进行物料输送。. 由带料盘的链节组成输送链来输送物料。. 通过对链节进行深度硬化以及对销轴和衬套进行有针对性的热处理,可以制造出非常 板式给料机 - BEUMER Group

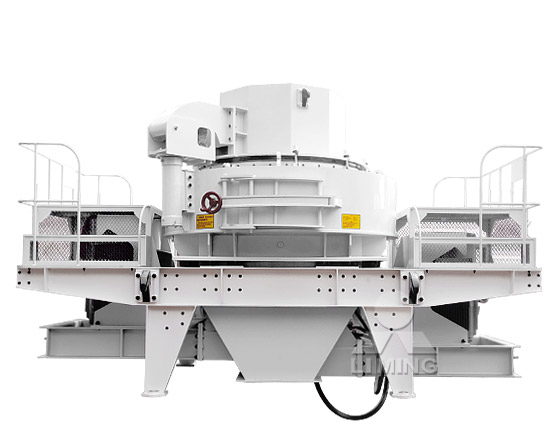

BDG波动辊式给料机_辊式给料机_复合式喂料机_给料机 ...

BDG波动辊式给料机. 生产能力:150-900T/H. 进料粒度:≤600mm. 筛孔不易被粘湿料堵塞. 无需水 变频设计 产量高客户端. 登录. 百度文库. 学前教育. 圆辊给料机计算. ©2022 Baidu 由 百度智能云 提供计算服务 使用百度前必读 文库协议 网站地图 百度营销. 圆辊给料机计算-.圆辊给料机计算_百度文库CN102032791B CN 200910044477 CN200910044477A CN102032791B CN 102032791 B CN102032791 B CN 102032791B CN 200910044477 CN200910044477 CN 200910044477 CN 200910044477 A CN200910044477 A CN 200910044477A CN 102032791 B CN102032791 B CN 102032791B Authority CN China Prior art keywords chute CN102032791B ... - Google Patents

CN104713362B - 一种镶嵌式烧结布料辅助装置 - Google Patents

CN104713362B CN201510120439.2A CN201510120439A CN104713362B CN 104713362 B CN104713362 B CN 104713362B CN 201510120439 A CN201510120439 A CN 201510120439A CN 104713362 B CN104713362 B CN 104713362B Authority CN China Prior art keywords limiting plate vertical limiting auxiliary device sintering feed power set CN107557571B CN201610503691.6A CN201610503691A CN107557571B CN 107557571 B CN107557571 B CN 107557571B CN 201610503691 A CN201610503691 A CN 201610503691A CN 107557571 B CN107557571 B CN 107557571B Authority CN China Prior art keywords preheating hot wind hot mixture roller Prior art date 2016-06-30 Legal CN107557571B - Google PatentsCN110749196A CN201911038428.4A CN201911038428A CN110749196A CN 110749196 A CN110749196 A CN 110749196A CN 201911038428 A CN201911038428 A CN 201911038428A CN 110749196 A CN110749196 A CN 110749196A Authority CN China Prior art keywords punching rod perforating material layer vertical direction Prior art date CN110749196A - 一种烧结机及其打孔透气装置 - Google Patents

CN204514041U - 一种镶嵌式烧结布料辅助装置 - Google Patents

CN204514041U CN201520156224.1U CN201520156224U CN204514041U CN 204514041 U CN204514041 U CN 204514041U CN 201520156224 U CN201520156224 U CN 201520156224U CN 204514041 U CN204514041 U CN 204514041U Authority CN China Prior art keywords limiting plate vertical limiting servicing unit sintering feed power set CN108317858B CN201810367137.9A CN201810367137A CN108317858B CN 108317858 B CN108317858 B CN 108317858B CN 201810367137 A CN201810367137 A CN 201810367137A CN 108317858 B CN108317858 B CN 108317858B Authority CN China Prior art keywords valve plate sintering machine rocker loose bin Prior art date 2018-04 CN108317858B - 烧结机小矿槽料仓 - Google PatentsCN102676797B CN 201210152045 CN201210152045A CN102676797B CN 102676797 B CN102676797 B CN 102676797B CN 201210152045 CN201210152045 CN 201210152045 CN 201210152045 A CN201210152045 A CN 201210152045A CN 102676797 B CN102676797 B CN 102676797B Authority CN China Prior art keywords sintering CN102676797B - 一种铁矿石烧结混合料布料的方法 - Google ...

CN114625096A - Google Patents

CN114625096A CN202210406714.7A CN202210406714A CN114625096A CN 114625096 A CN114625096 A CN 114625096A CN 202210406714 A CN202210406714 A CN 202210406714A CN 114625096 A CN114625096 A CN 114625096A Authority CN China Prior art keywords sintering sintering machine ore tank mixture machine Prior art date CN108317858A CN201810367137.9A CN201810367137A CN108317858A CN 108317858 A CN108317858 A CN 108317858A CN 201810367137 A CN201810367137 A CN 201810367137A CN 108317858 A CN108317858 A CN 108317858A Authority CN China Prior art keywords feed bin sintering machine valve plate hinge door chute Prior art date CN108317858A - 烧结机小矿槽料仓 - Google PatentsCN110749196B CN201911038428.4A CN201911038428A CN110749196B CN 110749196 B CN110749196 B CN 110749196B CN 201911038428 A CN201911038428 A CN 201911038428A CN 110749196 B CN110749196 B CN 110749196B Authority CN China Prior art keywords punching rod material layer perforating driving Prior art date 2019-10 CN110749196B - 一种烧结机及其打孔透气装置 - Google Patents

CN205906767U - 烧结烟气净化活性炭卸料储存装置 - Google ...

CN205906767U CN201620779946.7U CN201620779946U CN205906767U CN 205906767 U CN205906767 U CN 205906767U CN 201620779946 U CN201620779946 U CN 201620779946U CN 205906767 U CN205906767 U CN 205906767U Authority CN China Prior art keywords activated carbon storage device storehouse discharging sintering gas CN106949740B CN201610008003.9A CN201610008003A CN106949740B CN 106949740 B CN106949740 B CN 106949740B CN 201610008003 A CN201610008003 A CN 201610008003A CN 106949740 B CN106949740 B CN 106949740B Authority CN China Prior art keywords roller distributing device sintering segregation roller distributing Prior CN106949740B - 一种烧结混合料偏析布料装置 - Google PatentsCN108955260A CN201710350497.3A CN201710350497A CN108955260A CN 108955260 A CN108955260 A CN 108955260A CN 201710350497 A CN201710350497 A CN 201710350497A CN 108955260 A CN108955260 A CN 108955260A Authority CN China Prior art keywords power sintering main exhauster thickness speed Prior art date 2017 CN108955260A - 烧结系统主抽风机控制方法、装置及系统 ...

CN113299352A ... - Google Patents

2022年6月21日 CN113299352A CN202010844793.0A CN202010844793A CN113299352A CN 113299352 A CN113299352 A CN 113299352A CN 202010844793 A CN202010844793 A CN 202010844793A CN 113299352 A CN113299352 A CN 113299352A Authority CN China Prior art keywords material layer layer thickness CN207708777U CN201720804364.4U CN201720804364U CN207708777U CN 207708777 U CN207708777 U CN 207708777U CN 201720804364 U CN201720804364 U CN 201720804364U CN 207708777 U CN207708777 U CN 207708777U Authority CN China Prior art keywords activated carbon carbon material material room thickness width Prior CN207708777U - 一种活性炭排料装置 - Google PatentsCN115540606A CN202211167559.4A CN202211167559A CN115540606A CN 115540606 A CN115540606 A CN 115540606A CN 202211167559 A CN202211167559 A CN 202211167559A CN 115540606 A CN115540606 A CN 115540606A Authority CN China Prior art keywords sintering mixture bedding layer grate bars Prior art date 2022-09-23 CN115540606A - 一种烧结机的生产方法 - Google Patents

CN205164491U - Google Patents

CN205164491U CN201520746538.7U CN201520746538U CN205164491U CN 205164491 U CN205164491 U CN 205164491U CN 201520746538 U CN201520746538 U CN 201520746538U CN 205164491 U CN205164491 U CN 205164491U Authority CN China Prior art keywords temperature detecting device protective casing active carbon flange CN108955257A - 烧结系统主抽风机控制方法、装置及系统 - Google Patents 烧结系统主抽风机控制方法、装置及系统CN108955257A - 烧结系统主抽风机控制方法、装置及系统 ...CN113295000A - 一种基于料层厚度预测的布料控制系统及方法 - Google Patents 一种基于料层厚度预测的布料控制系统及方法CN113295000A ... - Google Patents

CN113299352B ... - Google Patents

CN113299352B CN202010844793.0A CN202010844793A CN113299352B CN 113299352 B CN113299352 B CN 113299352B CN 202010844793 A CN202010844793 A CN 202010844793A CN 113299352 B CN113299352 B CN 113299352B Authority CN China Prior art keywords material layer layer thickness rotating speed thickness sintering trolley